About Us

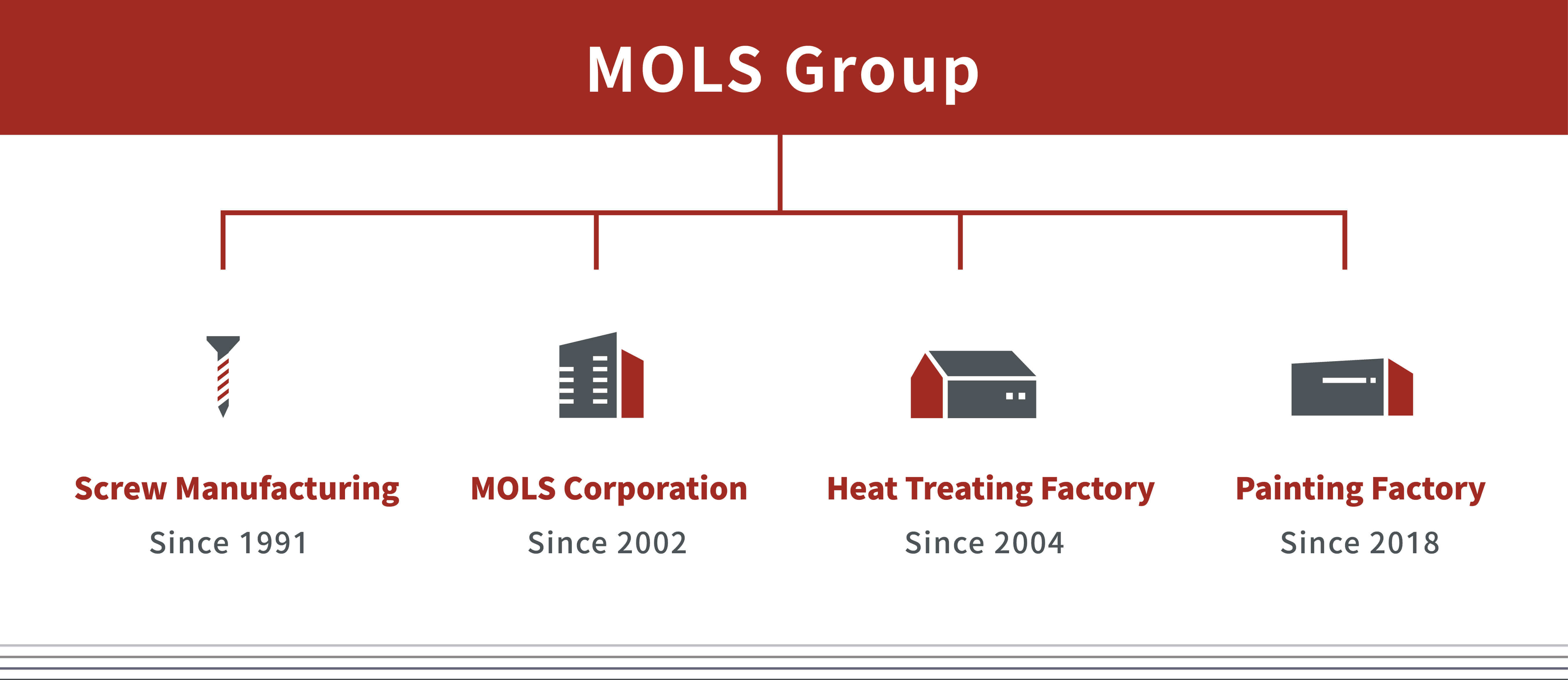

MOLS Group has over 30 years of experience in screw manufacturing and operates a supply chain system with screw manufacturing, heat-treating and painting. MOLS group expanded the business scope step by step. The screw manufacturing factory was set up in 1991, heat treat factory in 2004 and painting factory in 2018. All of our production factories comply with the government's environmental regulations as we care about the environment and do not want customers to worry about that the supply chain will be affected in the future. We hope that customers will never have concerns when choosing MOLS as a supplier.

With over 30 years of experience to focus on the supply in the US market, MOLS is familiar with what customers need. MOLS dedicates to quality improvement and treat customers' comments as treasure. We listen to customers and respond to their needs at our best.

Introduction of Modern Painting Equipment

MOLS Group has worked out an achievement in the head painted screws in recent years, especially on our largest sales category - Roofing Screws, and we also paint any screws that are required to head painting. In order to offer our customers steady lead time and good quality on painted screws, MOLS invested millions of US dollars to establish the painting factory as well as modern painting equipment. The customized modern automatic painting equipment has sufficiently increased the painting capacity and also avoid hand racking screws causing the unstable lead times. To ensure our customers having the good quality products, MOLS made a lot of effort to improve the screw performance in regard to drilling time and paint adhesion. The paint adhesion on screw heads and EPDM bonded washers is critical, so MOLS not only conducts the performance test with the testing machine but also imitates the real-world testing that how customers use the screws in their applications.

The Roofing Screws are used under the sunshine exposure and have to have good protection against UV, the paint masterbatch and ingredients that MOLS uses are high class for outdoor durables. The painting colors are customized to meet customers' needs, and we offer more than hundreds of colors to match customers' applications.

Various Options to Maximize Customers' Benefits

Like our company name reads, the 4 letters of MOLS stand for More Efficiency, Outstanding Quality, Less Cost and Speedy Service, which are our business philosophy that we want to do for all of our customers. MOLS is specialized in manufacturing various fasteners, such as Roofing Screw, Self-Tapping Screw, RV Screw, Gutter Screw, Self-Drilling Screw, Home Appliance Screw and Triangular Thread Screw that are used in various industries and received good feedback from the customers. MOLS is dedicated to providing our best to all of our customers and use our valuable resources to create maximum benefits for our customers.

With over 30 years of experience to focus on the supply in the US market, MOLS is familiar with what customers need. MOLS dedicates to quality improvement and treat customers' comments as treasure. We listen to customers and respond to their needs at our best.

Introduction of Modern Painting Equipment

MOLS Group has worked out an achievement in the head painted screws in recent years, especially on our largest sales category - Roofing Screws, and we also paint any screws that are required to head painting. In order to offer our customers steady lead time and good quality on painted screws, MOLS invested millions of US dollars to establish the painting factory as well as modern painting equipment. The customized modern automatic painting equipment has sufficiently increased the painting capacity and also avoid hand racking screws causing the unstable lead times. To ensure our customers having the good quality products, MOLS made a lot of effort to improve the screw performance in regard to drilling time and paint adhesion. The paint adhesion on screw heads and EPDM bonded washers is critical, so MOLS not only conducts the performance test with the testing machine but also imitates the real-world testing that how customers use the screws in their applications.

The Roofing Screws are used under the sunshine exposure and have to have good protection against UV, the paint masterbatch and ingredients that MOLS uses are high class for outdoor durables. The painting colors are customized to meet customers' needs, and we offer more than hundreds of colors to match customers' applications.

Various Options to Maximize Customers' Benefits

Like our company name reads, the 4 letters of MOLS stand for More Efficiency, Outstanding Quality, Less Cost and Speedy Service, which are our business philosophy that we want to do for all of our customers. MOLS is specialized in manufacturing various fasteners, such as Roofing Screw, Self-Tapping Screw, RV Screw, Gutter Screw, Self-Drilling Screw, Home Appliance Screw and Triangular Thread Screw that are used in various industries and received good feedback from the customers. MOLS is dedicated to providing our best to all of our customers and use our valuable resources to create maximum benefits for our customers.

MOLS Group Main Products

Main Product

Self Tapping Screw

Roofing Screw

Farmer Screw

Metal to Wood Screw

Metal to Metal Screw

Gutter Zip Screw

Triangular Thread Screw

Thread Forming Screw

Thread Rolling Screw

Self Drilling Screw

Self Piercing Screw

Home Appliance Screw

OEM orders

Self Tapping Screw

Roofing Screw

Farmer Screw

Metal to Wood Screw

Metal to Metal Screw

Gutter Zip Screw

Triangular Thread Screw

Thread Forming Screw

Thread Rolling Screw

Self Drilling Screw

Self Piercing Screw

Home Appliance Screw

OEM orders

Organizational Chart